The Industry Expert and Value Leader In Process Cooling Solutions.

Skillfully engineered temperature controllers, portable / packaged chillers and central chillers, cooling towers and pumping systems, provide Thermal Care customers with a wide range of process cooling solutions from off-the-shelf models to integrated, customized systems.

Portable and Packaged Chillers

An industrial Portable or Packaged Water Chiller refers to a unique design configuration of a self-contained chiller system that combines all necessary components including – the refrigeration circuit, controls and electrics, process pump and reservoir all within a single unit. Most often a Portable Packaged Chiller has a small footprint, is mobile and is located near the process being cooled. The capacity of these units usually range from 1-40 tons of cooling.

Central Chillers

An industrial central chiller is a piece of equipment used to provide cooling for multiple processes. The chiller incorporates both the refrigeration circuit and controls and is installed in conjunction with a pumping system. The pumping system can be integral to the chiller but often the two items are installed separately. Central chillers are used for higher cooling capacity requirements and offer a cost effective means to cool multiple processes without requiring a single portable chiller dedicated to each process. Central chillers are also highly energy efficient utilizing special compressor technology like oil free designs. The capacity of these systems can range from 10 to 250+ tons. The chillers are typically modular and can be added to a system in the future to expand the cooling capacity.

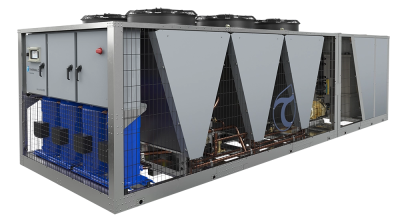

Packaged Outdoor Air Cooled Chillers

An industrial packaged outdoor air cooled chiller provides cooling for single or multiple processes and is located outside of the manufacturing facility. The chiller incorporates the refrigeration circuit and PLC in one package and requires a pumping system.

The pumping system can be integral to the chiller but often the two items are installed separately with the pumping system located indoors. When floor space inside the facility is unavailable, these chillers provide a perfect alternative that still meets the cooling requirements. Installation and operation are simple due to the packaged design with easy future expansion of up to 12 circuits, to match expanding cooling demand.

Packaged, outdoor chillers use air-cooled condensers to ultimately reject the process heat. These condensers utilize surrounding ambient air to provide cooling for the system. This eliminates the need for any support systems such as a cooling tower system for water-cooled chillers or interconnecting refrigeration piping for remote air-cooled systems.

Cooling Towers & Adiabatic Fluid Coolers

Industrial cooling towers are an effective way to remove unwanted heat from one place to another using water as the transport media. Cooling towers are an extremely cost-effective solution for process cooling when the temperature required is near 85°F or above. Water-cooled chiller condensers also typically require 85°F inlet water, so a cooling tower system is perfect for a water-cooled chiller system.

While there are a number of different manufacturers using various designs, all cooling towers operate using the same principle of evaporative cooling. A cooling tower removes heat from a process and rejects it to the atmosphere through the process of evaporation. The state change from liquid to gas absorbs large amounts of energy. Cooling towers are constructed of three major components: fan, fill, and shell. In a typical application, water is pumped through a process or process machinery where it removes heat. The warm water is pumped outside to the cooling tower where it is disturbed over the fill (a PVC structure design to increase available surface area) inside the cooling tower. An electrically powered fan moves air through the tower and causes a small portion of the water to evaporate which cools the rest of the water left in the cooling tower. This process operates more efficiently and provides much cooler water temperatures than simple fan-cooled air coils.

Temperature Controllers

A temperature controller is a piece of equipment used to maintain a designated temperature. A temperature controller can operate at elevated temperatures to either heat or cool a system as needed. The units incorporate a pump, heater, cooling valve and PID controller. Temperature controllers are available with a variety of configurations using a wide range of pump (3/4 hp to 10 hp), heater (9 kW to 48 kW) and valve (1/4 in to 1 in) sizes. The experts at Thermal Care will help you select the required configuration to best match the needs of your system.

Pumping Systems

Thermal Care offers a complete line of custom engineered pumping systems for cooling tower and central chiller applications with the highest quality design and construction features available. Standard, full sized pump trim, extended pump suctions legs, welded seams and solid steel decking under pumps and a PLC are just some of the value-added features incorporated into every system. Our selection of reservoirs, pumps, controls and alarms, plus complete engineering support from system design to plant layout drawings, assure you of the correct system for your application.

Plant Wide Cooling Systems

As one of the largest providers of heat transfer cooling solutions in the United States, Thermal Care’s expertise is in the design of plant wide cooling systems. A system typically is comprised of a central chiller, tank, cooling tower and other components such as a heat exchanger, water treatment, filtration, variable frequency drive, and/or 3 way valves. A system can be used for a single process or multiple plant wide applications.